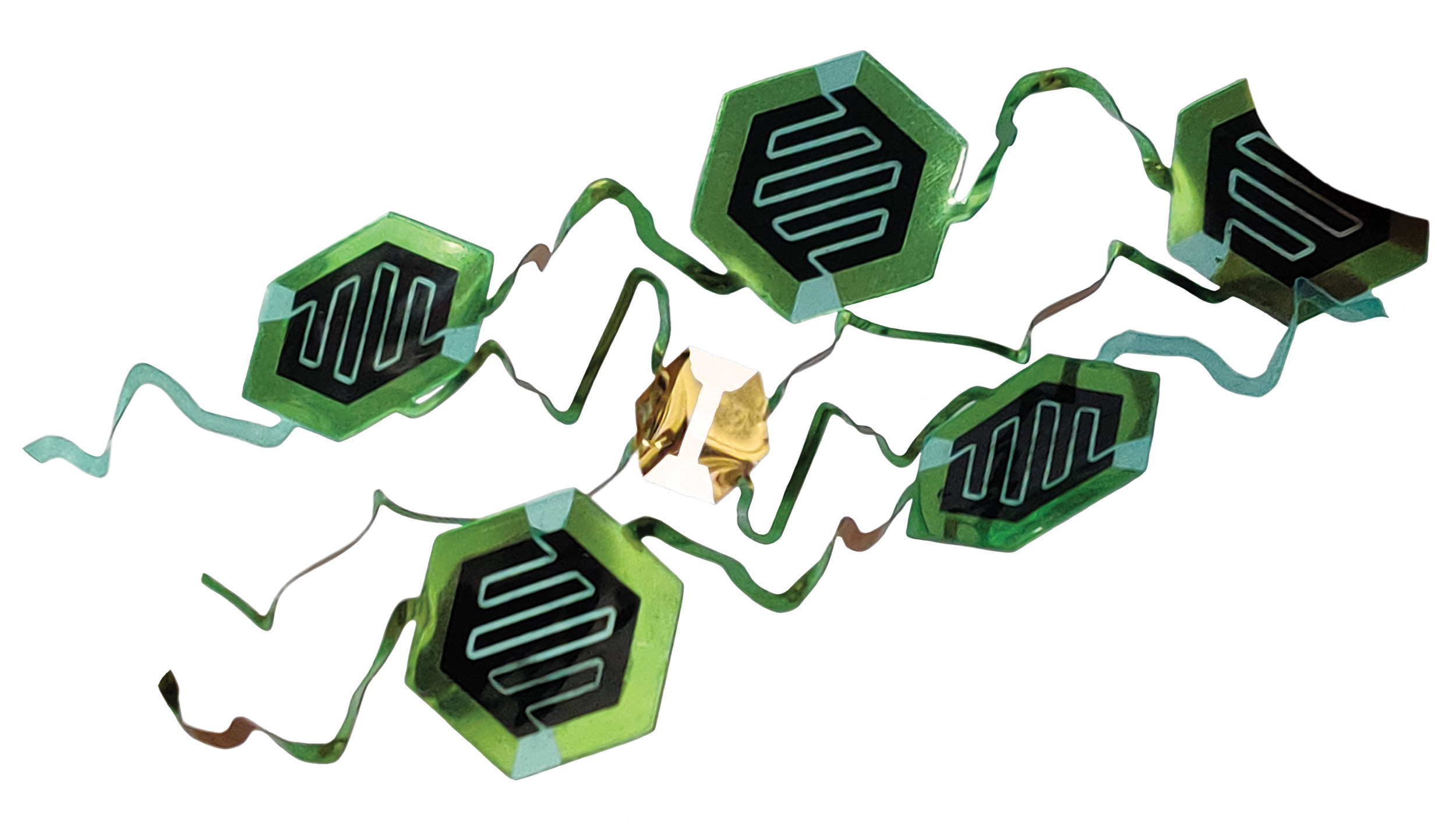

Custom-cut wearable sensors.(Image by Peisheng He)

Custom-cut wearable sensors.(Image by Peisheng He)Making the cut

Wearable sensors are often used by researchers to gather medical data from patients over extended periods of time. They range from adhesive bandages on skin to stretchable implants on organs, and they harness sophisticated sensors to monitor health or diagnose illnesses.

In the past, researchers have built systems for these devices using photolithography, a multistep process that uses light to create patterns on semiconductor wafers. But making wearable sensors this way requires a clean room and sophisticated equipment. Now, Berkeley engineers have developed a new technique for making wearable sensors that is simpler, faster and more economical, especially when making the one or two dozen samples that medical researchers typically need for testing.

This new technique replaces photolithography with a $200 vinyl cutter. The novel approach slashes the time to make small batches of sensors by nearly 90% while cutting costs by almost 75%, said Renxiao Xu (Ph.D.’20 ME). Xu and Liwei Lin, professor of mechanical engineering, were the study’s lead researchers.

To demonstrate the technique, the researchers developed a variety of stretchable elements and sensors. They attached an adhesive sheet of polyethylene terephthalate to a Mylar substrate, used a vinyl cutter to shape the surface, and attached sensor elements and other components to the contact pads. Then they used the vinyl cutter to carve the sensor’s contours, including spirals, zigzags and other features.

“Most researchers working on medical devices have no background in photolithography,” Xu said. “Our method makes it easy and inexpensive for them to change their sensor design on a computer and then send the file to the vinyl cutter to make.”

The researchers believe this technique could one day become a standard feature in every lab studying wearable sensors or new diseases. Prototypes could be designed using high-powered computer-aided design (CAD) software or simpler apps made especially for vinyl printers.

Learn more: Slicing the way to wearable sensor prototypes