Devices: Optimal distillation

In the hands-on Interactive Device Design course co-taught by mechanical engineering professor Paul Wright and electrical engineering and computer sciences professor Björn Hartmann, undergraduate students compete to come up with the best solutions to real-world problems. Last fall, winning team members Justin Kay, Carson Schultz, Claire Tuna and Matthew Visco researched the distillery business to design an elegant solution to an age-old challenge.

In the hands-on Interactive Device Design course co-taught by mechanical engineering professor Paul Wright and electrical engineering and computer sciences professor Björn Hartmann, undergraduate students compete to come up with the best solutions to real-world problems. Last fall, winning team members Justin Kay, Carson Schultz, Claire Tuna and Matthew Visco researched the distillery business to design an elegant solution to an age-old challenge.

Problem

Distilleries in the U.S. are required by law to track the volume in every barrel as it ages. Wineries can minimize oxygenation by topping barrels off when they lose about a liter of liquid. The measurement method commonly used throughout the industry today is by hand—a time-consuming and inefficient process.

Solution

Solution

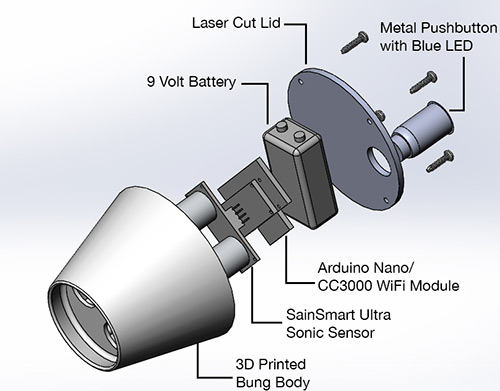

The team designed a sensing prototype that, when placed in the bunghole atop a barrel, automatically measures the distance to the surface of the liquid. The LED light indicates that the measurement is being sent to a wireless web server and converted to volume. Through a website, the user can set measurement intervals and monitor readings.

Result

The team estimates that replacing a standard bung with an electronic Büng could save distilleries about 160 hours of labor per 700 barrels each year. They are applying for a provisional patent for the device.