Dean’s word: Innovation by design

Step into room 122 of Hesse Hall on a weekday afternoon, and you’re likely to see more than 100 freshmen building—and then bending, melting and even breaking—their own product prototypes.

No, we’re not teaching students how to be destructive. Rather, we are introducing engineers to some unfamiliar behaviors: creative problem-solving using intuition, guesswork and a cheerful tolerance of failure.

The jobs of the future will not be on the factory assembly line, but in designing and building what’s in the factory.

Designers call this “the art of planning in the absence of complete information.” Here at Berkeley Engineering, we think it’s high time to embed the design discipline, and its own vocabulary and ways of thinking, into the engineering curriculum. That’s why we’ve enrolled 108 freshmen—far more than we initially expected—in a completely retooled class called E10: Introduction to the Design Cycle. The class is taught singlehandedly by Albert Pisano, a senior member of our mechanical engineering faculty as well as an ardent advocate for sparking creativity in engineering.

To make a device that measures the flexibility of plastic components, for example, the E10 students start by designing a computer model with CAD software. They’ll “print” the polymer prototype on a 3-D printer and then subject it to a series of tests. Throughout the process, they extemporize, iterate and ask a lot of questions.

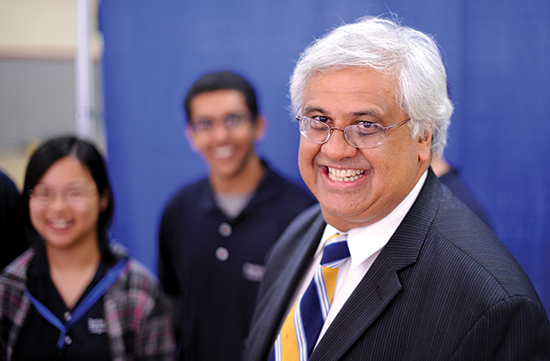

WELCOMING THE CLASS OF 2016: Dean Sastry led off engineering student orientation this fall, welcoming 618 freshmen and 242 transfer students, representing 35 states and 25 countries. Women make up nearly a quarter of the freshman class. (Photo by Noah Berger)“It’s more important that these questions get surfaced and asked than it is for them to be answered,” Al tells me. From the outset, the students are confronting issues related to user experience, sustainability, scalability and cost. “We’re completing their education by giving them a contextual framework,” he says.

WELCOMING THE CLASS OF 2016: Dean Sastry led off engineering student orientation this fall, welcoming 618 freshmen and 242 transfer students, representing 35 states and 25 countries. Women make up nearly a quarter of the freshman class. (Photo by Noah Berger)“It’s more important that these questions get surfaced and asked than it is for them to be answered,” Al tells me. From the outset, the students are confronting issues related to user experience, sustainability, scalability and cost. “We’re completing their education by giving them a contextual framework,” he says.

This hands-on immersion in design will not be limited to the freshman year. Across the curriculum, and in all departments, we want to see our students gaining experience in “design studios” that enable them to build and critique innovative prototypes, from tools and products to entire infrastructures.

And, because of Berkeley Engineering’s strengths on the manufacturing side, our students will learn how to convert prototypes into market-ready solutions. Our corporate partners tell us they want graduates “who can make things,” and we are happy to oblige.

Clearly, the U.S. economy will prosper only if we outfit workers with advanced skills in design and manufacturing, from robotics to nanotechnology. The jobs of the future will not be on the factory assembly line, but in designing and building what’s in the factory. We’re proud to be meeting this challenge with Berkeley’s own blend of ingenuity, creativity and bold ambition.

—S. Shankar Sastry

Dean and Roy W. Carlson Professor of Engineering

Director, Blum Center for Developing Economies