Materials science and engineering professor Junqiao Wu, photographed

with a thermographic camera in Hearst Memorial Mining Building. Instead of detecting

visible light, thermographic cameras typically detect radiation in the long-infrared range

of the electromagnetic spectrum (roughly 9,000–14,000 nanometers or 9–14 μm), making

it possible to see one’s environment through tiny changes in temperature. (Photos by Adam Lau / Berkeley Engineering)

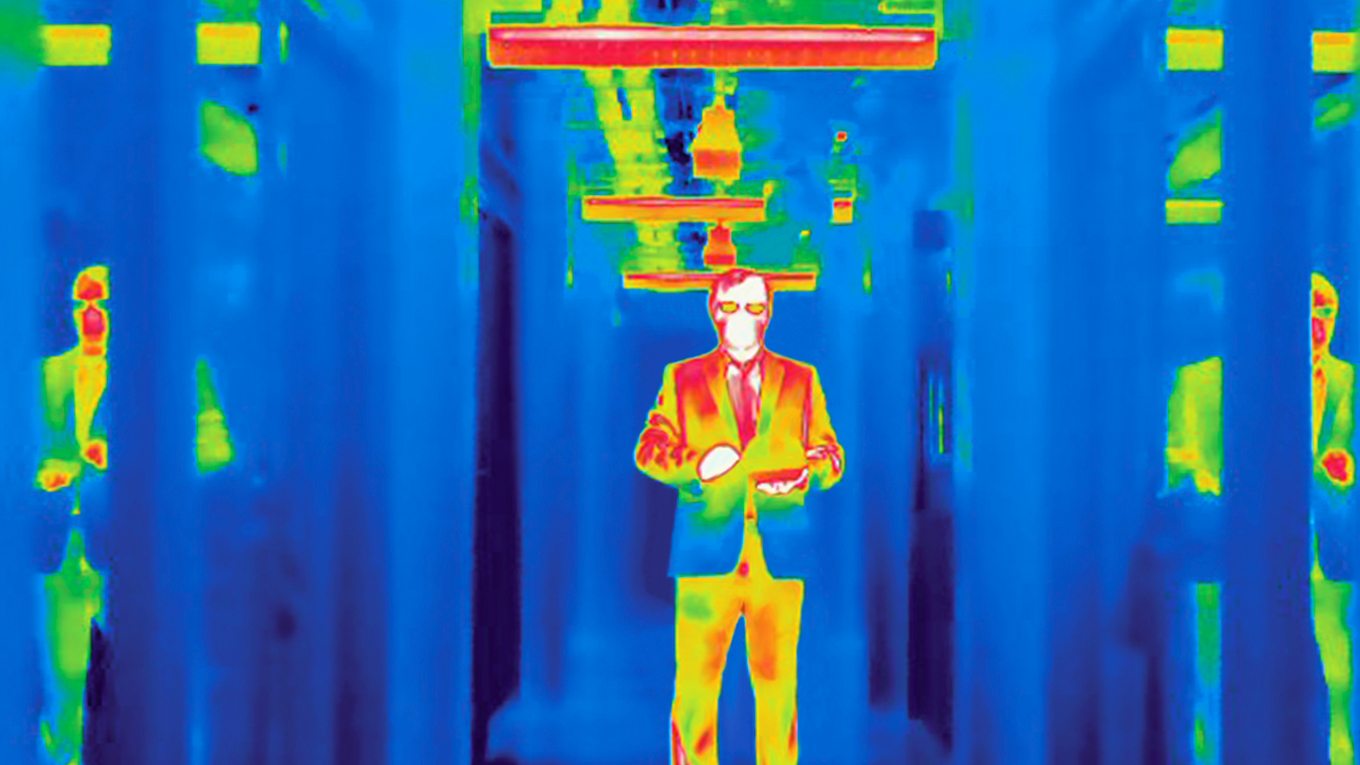

Materials science and engineering professor Junqiao Wu, photographed

with a thermographic camera in Hearst Memorial Mining Building. Instead of detecting

visible light, thermographic cameras typically detect radiation in the long-infrared range

of the electromagnetic spectrum (roughly 9,000–14,000 nanometers or 9–14 μm), making

it possible to see one’s environment through tiny changes in temperature. (Photos by Adam Lau / Berkeley Engineering)The transformer

To anyone unfamiliar with the world of chemical compounds, vanadium dioxide sounds like something that the “Star Trek: Enterprise” crew might have to battle a few aliens to get their hands on. But this oxygen-infused variant of the chemical element vanadium is indeed real and has a notable characteristic: It can change from an insulator to a metal.

Whether we learned about phase change as kids eagerly waiting for popsicles to freeze or watching a science teacher turning a liquid to gas with a dramatic poof, most of us understand the concept: when a material changes from one physical state to another – usually solid, liquid or gas – without altering its chemical make-up. Water, for example, is H2O whether it’s in a liquid or a solid state.

Vanadium dioxide’s phase change lacks the visual flair of turning to ice or gas, but it is much more novel: It toggles between conducting and not conducting electricity. When heated to 152 degrees Fahrenheit — about the temperature of a hot cup of tea just starting to cool down — the dark, solid material changes from blocking the movement of electricity to letting it flow.

Materials science professor Junqiao Wu has been working with the compound, VO2, for a decade, at first probing its unusual physical properties. But a few years ago, he began developing real-world technologies with the metal.

“I started thinking, this phase transition is unique — it must have some new applications,” he says.

He bundled several related research projects into an entry for the Bakar Prize, a 2020 addition to UC Berkeley’s Bakar Fellows program, which provides robust support for a faculty member to move commercially promising work beyond the lab and into the market.

Wu won the prize’s inaugural award — a generous $225,000 financial infusion to his lab. As a result, three applications of vanadium dioxide are in various stages of development and hold potential for exciting advances in biomedical, engineering, energy and military technologies.

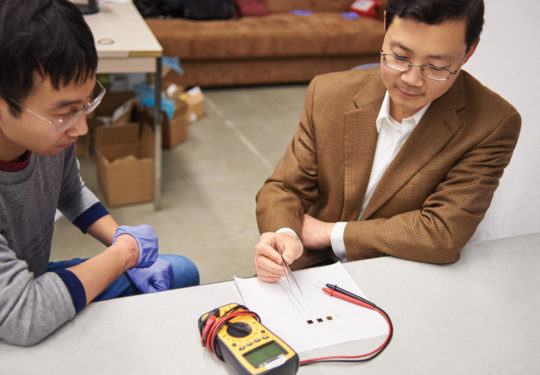

Kechao Tang and Junqiao Wu examine samples of ultra-thin vanadium dioxide films that switch automatically between conducting heat and insulating against it. (Photo by Mark Joseph Hanson)

From cooling to warming

Wu got one of his inspirations by looking up. He’d noticed a roofing technology called radiative cooling that’s been on the rise in recent years. The coating, marketed as shingles and panels by a few startups, radiates infrared heat waves off of a building and out into the atmosphere, keeping buildings cool without using any energy.

While that may be effective for perpetually hot climates such as equatorial regions, Wu says, “Whenever I’d see that technology, I would ask myself, what about in winter? Your roof will continue to do the same thing — take the heat energy and radiate it out. That’s not what you want to be doing in winter, right?” He notes that by “winter,” he means any significant cool-down, like the Bay Area’s fog-chilled nights.

Vanadium dioxide, he thought, with its novel temperature-driven phase transition, could enable a technology that radiates heat off of buildings when ambient temperatures are warm, and then, when the temperature drops, changes to a non-radiative state to keep heat in.

To create this smart, all-weather roofing material — he calls it temperature-adaptive radiative coating, or TARC — Wu and his team developed vanadium dioxide into an ultra-thin film. On a balcony at his Berkeley Hills home, the team monitored the experiment continuously over several days. In warm temperatures, the small, TARC-covered panels radiated heat efficiently, and when temperatures cooled down to below 70 Fahrenheit, the panels switched off the radiative cooling, allowing the space underneath them to warm up.

How, exactly, does the material know when to make the switch? The secret sauce is tungsten, a dense metal common in metal alloys. Infusing, or “doping,” the vanadium dioxide with tiny amounts of tungsten — just 1–3% — creates a built-in thermostat, effectively programming the material to enter its phase transition at a desirable threshold, such as 50 or 60 degrees Fahrenheit.

Wu’s team — which included postdoctoral researchers Kechao Tang, now a faculty member at China’s Peking University, and Kaichen Dong, together with Wu’s students — designed and analyzed the experiment. The film they produced is just a tiny fraction of a micrometer thick, much thinner than a human hair.

Naturally, working at that scale is complex. The researchers compress mixed powders, Dong explains, then hit them with a high-powered laser, causing clusters of atoms to fly out and form a film on a glass positioned above the powders. “That’s why we call it ‘growing the material’ — because if you look at this piece of glass, you can see the thickness increase as more and more material lands on it,” he says. Transferring the resulting film onto cellophane tape causes the rigid material to take on the tape’s flexible characteristics.

In addition to the Berkeley Hills experiment, the team used year-round weather databases to run simulations of their film’s performance in typical weather conditions for cities around the world. “We proved that our device would save a lot of energy in temperate-zone cities like Chicago, Boston and New York,” Wu says. The team submitted their results for publication this fall.

The road to commercialization is still a long one. Dong, who also spent two years as a visiting student in the Wu lab, notes that to produce the film at a manufacturing scale, the team must re-optimize all their measurements. “We’re starting again at the design stage to ensure the manufactured materials will achieve the same performance level as the grown material,” he says. “We’re working as both scientists and engineers.”

Turning up the heat

Wu’s lab is also growing a different tungsten-doped vanadium dioxide film to improve a well-known technology: thermography. Infrared cameras read temperature variations across an object to create those glowing red, orange and green thermal images often associated with night vision goggles. They measure infrared energy, the invisible wavelengths that objects radiate when they have any measurable temperature. In addition to some medical scans, thermography is used to check electronics for faulty connections and to scan buildings for hidden structural problems.

However, as those nebulous images suggest, the technology is not very precise; its usefulness has been limited by its low resolution. Higher sensitivity readings would help make more meaningful, even critical distinctions between similar points in a scan.

“People in manufacturing or industry spend a lot of money to improve infrared cameras,” Wu says, but his team flips that approach. “Instead of improving the camera, we coat the surface of the thing we’re imaging.” Placing his ultra-thin smart film over an object sensitizes its surface radiation, allowing the camera to image it more efficiently.

The resulting image is 15 times more sensitive to small temperature variations on the surface compared to currently available thermography methods. “If you want to improve the sensitivity of a camera by 15 times, that’s a lot more expensive and a lot bulkier,” Wu says. With his smart film method, “Using the same camera, you will see a lot more.”

Like the roof coating, the smart film, called thermal imaging sensitizer, is tape-based, so it can go on almost any solid surface. Currently, the team can make only smaller pieces, but they are exploring how to cover larger areas by spraying it onto the surface of a building or bridge, for example, to enhance safety inspections with infrared imaging.

“We’re trying to come up with a new way to apply nanoparticle film over a large area without the need for complicated high-energy lasers,” says Dong. “A spray will allow us to add a thin layer of nanoparticles directly onto the target area,” adding sensitivity to make tiny, sub-surface cracks or structural flaws visible with an ordinary infrared camera.

A study with mice also has demonstrated the vanadium dioxide film’s potential usefulness in early cancer detection. Wu’s team took smart-film-enhanced thermal images of mice with cancer and detected tumors where existing technology — optical imaging and standard thermography — did not. Two days later, the other technologies corroborated the location of the tumors the vanadium dioxide film had found earlier. Four days after the earliest findings, the tumors were large enough that bumps could be visually observed. The work will be published in the journal Science Advances this year.

Wu expects the technology will have the largest impact in the early detection of breast cancer, where tumors are close to the skin’s surface, accessible to thermography. His team will also research comparable biomedical applications such as vascular conditions and skin cancer.

Hidden in plain sight

For another application, instead of increasing the visibility of objects in thermal scanning, Wu hides them. Thermal camouflage technologies — evading the detection of night vision goggles, for example — already exist, conjuring spy-versus-spy covert operations with obvious appeal for military and other surveillance and counter-surveillance applications. But they’re still clumsy, require energy input to work and have rigid, cumbersome structures. They also have glitches — when a hidden object’s temperature changes, it becomes momentarily visible while the devices adjust.

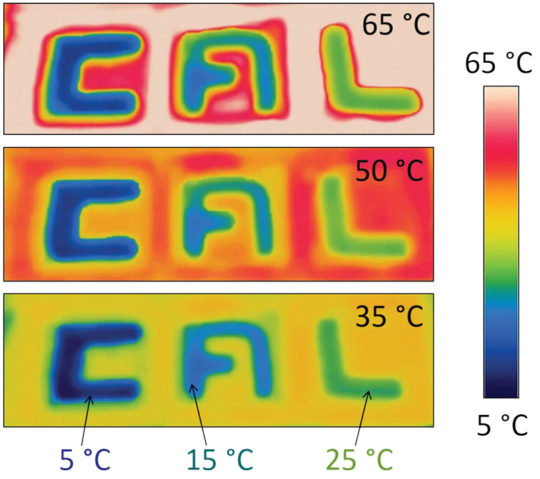

New technology can fool infrared cameras into perceiving a thermal image that is different from what the camera is actually measuring. Here, the letters C-A-L appear cool even when the real temperatures are hot.

The vanadium dioxide-based system is “power-free, monolithic and mechanically flexible,” according to a paper published in Advanced Materials in July, and continues to work even when the target object’s temperature surges.

But Wu’s team went further than camouflage. They created a way to fool infrared cameras into “seeing” a thermal image that’s different from what the camera is actually measuring. In a spirited party trick, researchers made a “Cal” logo appear on a thermographic image, indicating completely different temperature settings than the real temperatures of the C, A and L actually being imaged.

“The decoy would not only passively conceal the real thermal activity of the object from an infrared camera, but also intentionally fool the camera with a counterfeit infrared image,” the paper says. Put more simply, it’s a total fake out.

While the decoy findings suggest Hollywood-inspired technology — for example, making a 98.6 Fahrenheit reading for a human appear more like a tree — Wu confesses that mainly he set out just to test a theory about manipulating infrared waves.

“We were just curious,” he says with a playful smile.

Onward and inward

To commercialize the Bakar work, Wu and his students — with help from Berkeley’s innovation ecosystem, including SkyDeck and CITRIS Foundry — have launched the startup DeepRed Technologies. Much of the company’s current effort is focused on scaling up, but the lab is exploring scaling down, so to speak: Wu is conceiving of a way to use his signal-amplifying smart film at the cellular scale.

By putting the film onto a clear base — a substrate — and placing cells on top, “You can probably use an infrared camera to look up through the bottom and see individual cells,” he says. And not just the form of the cells, he adds, but possibly their interactions and even slight temperature differences, down to a thousandth of degree Centigrade.

As far as he knows, no one’s taken the temperature of individual cells before. If his ideas bear fruit, they have the potential to open up whole new areas of biological and medical inquiry.

“All of a cell’s biological and metabolic activities probably will reflect onto their local temperature,” Wu says. “If we can amplify that, so that you can see it with a regular infrared camera, that would be wonderful, right?”