Ashok Gadgil and Ph.D. student Dana Hernandez, right, test new technology at Gadgil’s Davis Hall lab. (Photos by Adam Lau / Berkeley Engineering)

Ashok Gadgil and Ph.D. student Dana Hernandez, right, test new technology at Gadgil’s Davis Hall lab. (Photos by Adam Lau / Berkeley Engineering)Safe to drink

Every day in Bangladesh and neighboring West Bengal, India, tens of millions of people drink water containing deadly levels of arsenic. Although awareness of the problem dates to the early 1990s — and in 2000 the World Health Organization named it the largest mass poisoning in human history — no large-scale solution yet exists. The largely poor, historically marginalized people living in this region have no choice but to drink the toxic water.

And it’s not just a problem in Southeast Asia. Communities in South America, Alaska and California’s Central Valley also have contaminated groundwater, putting residents’ health at risk. Long-term exposure to arsenic through drinking water, even at low levels, can have dire consequences. The list of potential health effects includes internal cancers, cardiovascular disease, skin lesions and disfigurement and, among young people, impaired cognitive development.

Ashok Gadgil, professor of civil and environmental engineering, desperately wants to help. He has found an affordable, scalable way to remove arsenic from water that his track record suggests just might work. Across five decades at UC Berkeley and Lawrence Berkeley National Laboratory, he has cultivated an uncommonly broad humanitarian perspective in his work as an engineer — one that wields innovation and design to address serious challenges affecting human health and well-being, particularly among the poor. “The central point of our work is to bring science to solve real problems on a societal scale,” he says.

In the 1980s, Gadgil developed patents for solar heaters and even moved to India for five years to deploy them — but was ultimately foiled by politics and bureaucracy. In the 1990s, he invented a technology that uses ultraviolet light to disinfect water, killing disease-causing pathogens like cholera. Today, it is widely used by WaterHealth International to provide purified drinking water to nearly 30 million people throughout India and Africa.

Then, in the early 2000s, Gadgil began researching safer wood-burning cookstoves for residents of developing nations, particularly displaced women at refugee camps in Darfur, Sudan. Because wood is scarce in the region, women would trade food rations for fuel or venture far from the camps to source wood, leaving them vulnerable to assault. Having more efficient stoves that reduced wood-fuel demands would help these women and protect them from violence. Ultimately, Gadgil led the design and development of the Berkeley-Darfur Stove and co-founded the nonprofit Potential Energy to oversee the manufacture and distribution of the stoves in Darfur refugee camps and, more recently, Uganda. To date, more than 50,000 stoves have been distributed.

Affordable, effective, community-scaled

When his lab’s research on stoves ended earlier this year, Gadgil found himself with a singular focus on another class of technologies he first began exploring in 2005: low-cost arsenic removal from contaminated groundwater. For afflicted communities, this should come as good news.

A naturally occurring element, arsenic is widespread in the earth’s crust. Depending on geology, aquifer depth and other factors, it can dissolve from certain rock formations and accumulate in groundwater. By drinking water from wells that access this water, people can be exposed to harmful levels of the highly toxic metalloid.

But removing arsenic is notoriously difficult and expensive. While treatment may be within reach for larger, well-funded water systems, with existing technologies it is typically not feasible for small, rural and low-income communities. That’s why Gadgil has worked for more than 15 years to develop affordable, effective, community-scale arsenic removal technologies.

Most significantly, a technology his research group began working on in 2005 — called ElectroChemical Arsenic Remediation (ECAR) — has operated successfully since 2016 at a rural high school outside the West Bengal capital of Kolkata, India. Installed inside a large converted classroom, the system treats water drawn from a nearby well to remove arsenic levels from a dangerously high 250 parts per billion (ppb) all the way down to 3 ppb, well below the World Health Organization’s recommended standard of 10 ppb.

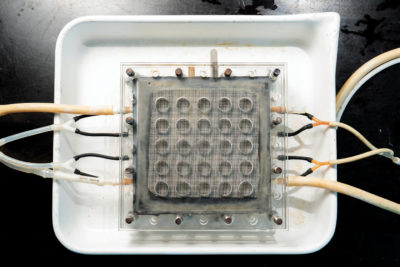

The technology builds upon a common process known as electrocoagulation, in which an electric current is passed through water to precipitate dissolved and suspended solids. At the India ECAR plant, a total of 32 one-meter-by-one-meter steel plates, submerged in two large tanks holding up to 1,400 liters each, are electrified with about 10 volts of DC power to rapidly release a particular kind of rust from the steel plates. Arsenic in the water naturally binds to the iron oxides in this rust, and together the denser particles sink to the bottom for easy extraction.

It takes about 100 minutes for each tank or reactor to clean 1,000 liters, says Siva Bandaru (Ph.D.’20 CEE), a postdoctoral researcher in Gadgil’s lab who helped develop the system. Operated for profit by an Indian licensee, the plant provides up to 10,000 liters per day of safe drinking water to the school, for free, and to about 3,000 members of the surrounding community, for less than 1 cent per liter. It generates surprisingly little waste — about one-third of a cup of sludge per person per year — which Gadgil’s Indian partners are looking to incorporate into concrete bricks for safe immobilization.

California’s hidden water crisis

Almost 300 public water systems in California deliver water containing high levels of arsenic. For geological reasons, most of these are concentrated in the state’s Central Valley, where the challenge is compounded by familiar risk factors including poverty, political under-representation and air and water pollution tied to the valley’s intensive agricultural use. Here, in the fertile center in one of the largest states in one of the wealthiest nations on the planet, another arsenic crisis quietly plays out every day.

About 95 miles northwest of Bakersfield in the South Valley lies a small town called Allensworth. Little known now, it has a rich history dating to the early 20th century and holds the honor of being the first California town established by Black Americans. Like many towns in the valley, it sits on groundwater contaminated with unsafe levels of arsenic. Also like many neighboring communities, it lacks the funding and expertise to remove the arsenic, leaving its 500 or so residents reliant on costly bottled water.

When Gadgil learned about the town’s predicament — and that its current leadership was actively seeking ways to solve the water problem and revive the economy — he thought he might have a solution.

Water demands and labor costs are far higher in California than in rural India or Bangladesh. So rather than trying to shoehorn ECAR into a situation vastly different from that for which it was designed — one in which ease of use and availability of materials are paramount — Gadgil and his research team realized they needed something faster and more powerful.

The result was a pair of advanced arsenic-removal technologies based on the ECAR platform called Air-diffusion Cathode Assisted Iron Electrocoagulation (ACAIE) and Fe/iron Electrocoagulation with External Oxidizer (FOX).

In ACAIE, the iron cathode is replaced with an air cathode that takes in oxygen from the air and releases hydrogen peroxide into the water. In water, hydrogen peroxide reacts with iron ions thousands of times faster than dissolved oxygen does in ECAR. ACAIE takes up a tenth as much space as ECAR to treat the same volume of water — and does so in four-hundredths of the time, Bandaru says.

FOX also relies on hydrogen peroxide, either from an ACAIE cathode or other external source. It further speeds up reaction times in water with low salt content or conductivity by replacing the iron plates, typically spaced 2.5 to 3 centimeters apart, with paired iron sheets sandwiching a thin plastic mesh, reducing the distance between them to just a few millimeters.

In the summer of 2019, a one-week test of the two new technologies in Allensworth served as a successful proof of concept and could potentially point toward an arsenic-free future for the town. Graduate student researcher Sara Glade led the charge, designing and implementing the trial.

“Sara [and her team] proved with very careful experiments that we can remove arsenic from their groundwater in Allensworth, reliably and inexpensively,” Gadgil says. “What we did in India and Bangladesh could work in Allensworth.…We are satisfied that it will work perfectly well.”

‘Another door opens’

Despite the success of the trial, which was locally funded with Glade’s support, the community or state will still need to come up with the money to install a permanent, properly sized treatment plant. Gadgil estimates this could run between $500,000 and $750,000. Because this will be the first demonstration project, this includes the cost of detailed monitoring, verification and rectifying unexpected problems that might emerge during the scale-up. So the project in Allensworth remains on hold.

“When one door closes, another door opens,” Gadgil says — 45 miles to the north, to be precise. With a population of around 26,000, Lemoore is much larger than Allensworth. Some of its residents already have access to safe tap water. Yet the Central Union Elementary School, which is in a rural, unincorporated region of Lemoore and operates its own water system, does not.

At this school, groundwater is used only to water the lawn, and all water fountains have been turned off. Instead, the school purchases five-gallon bottles of drinking water that are placed on water-dispensing stands throughout the campus.

In 2019, Gadgil received a $900,000 grant in collaboration with Berkeley’s School of Public Health to fund a three-year effort to further evaluate ACAIE technology. “If successful,” Gadgil wrote in the grant application, “this project will bring us closer to solving the arsenic crisis in rural California.”

Central Union Elementary was the perfect test case. As in Allensworth, its leaders were eager to find a solution to their arsenic problem. The Berkeley team began working closely with the school last year to create both a small treatment facility in a vacant classroom and complementary modules in STEM curriculums at different grade levels, which will teach children about water safety and treatment. If successful, the treatment facility will provide safe water to the school at no cost once installed, mirroring the project in India.

Progress was interrupted by the COVID-19 epidemic in March, and while work on the treatment units has since resumed at a slow and careful pace in Berkeley, the field trial itself won’t begin until after restrictions on travel and other activities are lifted. Meanwhile, curriculum development and student engagement continues — with remote learning as a new twist, says Winston Tseng, associate professor of research with the School of Public Health, who is leading the project’s outreach and education components.

Tseng and his team of two graduate students, two undergraduates and one other faculty member also actively consult with Central Union parents, teachers and school administrators, and with the local Tachi-Yokut Tribe, whose children represent a significant proportion of the student body.

“They continue to support the work to pilot this new innovative technology at the school,” said Tseng. “They appreciate that UC Berkeley cares about this rural community and Central Union. We’re building this relationship.”

Bandaru, who also worked on the Allensworth trial and is now involved in the Lemoore project, says he thinks ACAIE’s improved speed and efficiency will allow it to eventually overtake its predecessor. “From a technology point of view, it’s flawless,” said Bandaru, who is also training a delegation from the Philippines on the technology. “I think it’ll scale up more rapidly than ECAR.”

If the plant in Lemoore works as well as the team hopes, it could provide a foundation for deploying ACAIE not only throughout California’s Central Valley but also back in India and Bangladesh, bringing the work of Gadgil’s lab full-circle — and showcasing its commitment to real-world solutions, not specific technologies.