Project supplies await pick-up at the Jacobs Project Support (JPS) center, a fully automated project-tracking system that notifies students of the state of their projects as they’re fabricated.

Project supplies await pick-up at the Jacobs Project Support (JPS) center, a fully automated project-tracking system that notifies students of the state of their projects as they’re fabricated.At Berkeley Engineering, creativity still shines through remote learning

A typical Berkeley Engineering education features hands-on learning, collaborative teams, real-word engagement and access to cutting-edge equipment. As at other universities nationwide, the college has had to pivot to virtual instruction due to the COVID-19 pandemic. But because engineers excel at finding creative solutions to any challenge, many of its programs evolved over the past seven months to boost innovation and collaboration through remote formats.

For example, 275 micro kits were either picked up or shipped to students, including an array of parts and tools to support the learning of electrical and mechanical hardware fundamentals in core mechanical engineering courses. In bioengineering, where a hallmark of upper-division courses is project- and team-based learning, the department worked with Jacobs Project Support Services and the Mechanical Engineering student machine shop to provide access to prototyping and testing resources.

Students in bioengineering courses have also been able to collaborate remotely with medical partners on such projects as:

- A product for pulmonary nurses and respiratory therapists that indicates when it’s time to replace or clean PPE

- Relieving mask pressure points for dental hygienists in order to reduce fatigue

- A method to keep the inside of the mask cool for medical refugee camp personnel working at the border under hot environmental conditions

- Reducing the claustrophobic effects on patients wearing masks inside MRI machines

- Preventing the spread of COVID-19 within Cal Athletics’ healthcare field workers

- A method to effectively prevent fogging for optometrists conducting visual exams while wearing masks

- Countering the voice attenuation in respirators for emergency department resuscitation teams to improve intra-team verbal communication

“My experience with teamwork has been surprisingly positive during COVID,” says graduate student Diego Espinoza. “While nothing can surpass face-to-face interaction, an advantage of remote learning is flexibility. We can meet as teams for classes and projects at times and frequencies that fit our chaotic schedules. Normally, this wouldn’t be feasible in traditional in-person settings.”

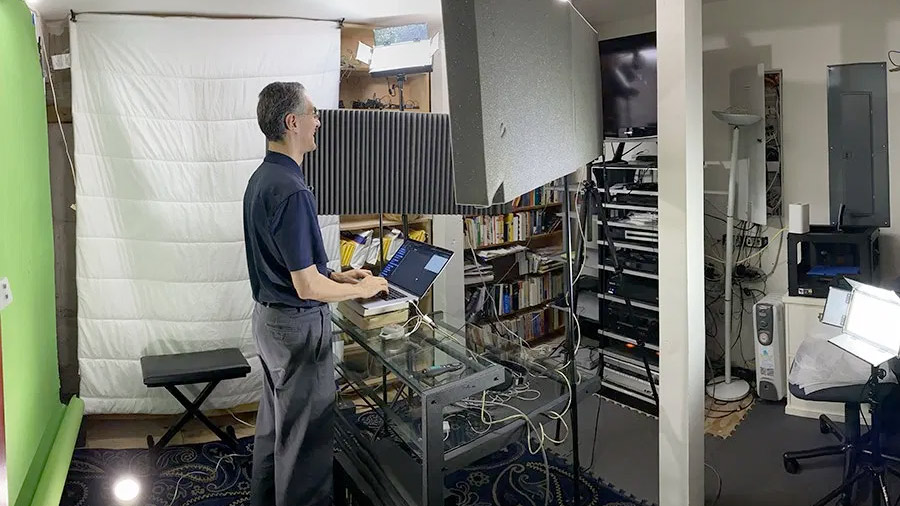

Remote learning has presented even greater challenges for Berkeley Engineering’s centers and institutes that emphasize team collaboration and maker projects. Here are a few examples of their adaptations:

The Jacobs Institute for Design Innovation

As a makerspace, Jacobs Hall typically serves more than 1,400 students, instructors and researchers each semester. Because it has been closed to all non-essential members, its technical team has developed project support services that allow eligible students, faculty and staff to submit files for parts fabrication, including metal, wood and acrylic laser cutting; 3D printing; and most other rapid prototyping processes.

In April, the institute launched the virtual COVID-19 Design Challenge: Enabling Our Communities to Safely Reopen and Rebuild, a three-week team challenge to develop solutions that address the pandemic and the future issues it will pose for communities. Topics addressed such issues as reducing and preventing infection, thriving during quarantine and ramping back up when restrictions are lifted.

In addition, through a series of webinars, the institute continues to offer its Design Conversations and Design Field Notes speaker series. Its summer Design Showcase also moved online, featuring live Zoom presentations of student projects from five courses as well as its newly launched Design Scholars Program. Virtual workshops on such concepts as fusion, solid modeling, computational art and simple circuitry were also made available. These programs will continue by semester during fall 2020 and spring 2021.

“I needed a prototype laser cut for the Design and Cybersecurity course,” says undergraduate student Katrina Priya. “I was concerned about how physical prototyping would work in this remote setting, but it actually turned out great. It was cool to see something I designed on a screen show up at my doorstep within just a few days!”

The Fung Institute for Engineering Leadership

The Fung Institute’s MEng Career Development team has launched a new initiative of 15 student-driven Affinity Groups to encourage incoming students to collaborate through engagement based on their career interests and goals with activities such as industry-specific events, speaker engagements, alumni mentorship and social networking.

The institute’s career management platform, FI Connect, has added a feature that enables students and recent alumni to apply for microprojects that connect their online learning to real-world experiences. Some examples of microprojects include User Research for New Products, Content Marketing for Non-Profits and Supply Chain Data Analysis. And its Bridges program offers short-term internships or students and recent graduates to gain professional experience with guidance from alumni.

And its Capstone-at-Home initiative enables faculty advisers and industry partners to ship test devices to students. To date, six projects are underway, involving VR systems; IoT device development; robotics; bioengineering using depth cameras and wearable sensors; and embedded sensors and artificial intelligence.

“Finding ways to prototype was challenging due to the distance,” says undergraduate student Kayla Hidayat. “Since our team was creating a 2D prototype for our summer project that also required wire-framing, we used collaborative platforms like Figma. It enabled us to work on the project at the same time while in different locations.”

The Sutardja Center for Entrepreneurship & Technology (SCET)

SCET offers an Innovation-X Roundtable video series and created a Best of SCET series to deliver small TED-style talks by instructors for international students studying at Berkeley. The center’s largest class — the A. Richard Newton Lecture Series, which attracts 450 students — has moved online. SCET also moved its executive programs online, including Data-X Live, Online and Engineering Leadership Global.

For more insider perspectives on conducting design courses during COVID, check out this article on Medium.