Mother of invention

“We tried a standard toaster oven as well as a laboratory-grade oven. . . . Uniform heat on a flat surface will ensure that the Shrinkies re-flatten . . . A post-bake of seven minutes after shrinkage greatly smooths the ink features . . . “

It sounds more like a recipe than an inventive scientific approach to fabricating cheap microfluidic devices. But, after her innovation was featured and published online in Lab Chip, Michelle Khine (B.S.’99, M.S.’01 ME; Ph.D.’05 BioE) was told it had more downloads in one month than any other paper previously posted by the UK’s Royal Society of Chemistry, one of the world’s leading scientific publishers.

YOUNG INNOVATOR: Michelle Khine (B.S.’99, M.S.’01 ME; Ph.D.’05 BioE), UC Irvine assistant professor in biomedical engineering, was recognized by Technology Review in 2009 for her innovation using a childhood toy to fabricate chips for her microfluidics research. (Photo by UC Merced.)

“I’m a very impatient person,” Khine says, explaining her Eureka moment. “I wanted to figure out how I could set things up really quickly.” It was 2006, in her lab at UC’s newest campus in Merced, where there was no sophisticated equipment like she’d used at Berkeley and in her jobs at Sandia Labs and Fluxion Biosciences. Then it popped into her head: Shrinky Dinks®, one of the educational toys her mom brought home to nourish young Michelle’s creativity.

“We loved to stick them in the oven and watch as they would curl and shrink,” Khine says. The kids’ arts-and-crafts kits peaked in popularity in the 1980s. But the thermoplastic sheets of polystyrene, which can be drawn on and baked to make tiny charms—or anything else for that matter—are still widely available at crafts and toy stores.

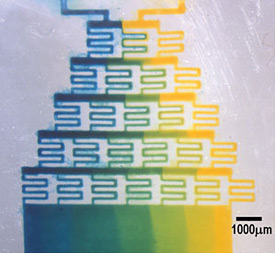

Khine printed microfluidic patterns onto the Shrinky Dink sheets using a laser-jet printer, then heated them in a toaster oven. As the pieces flattened out into hard plastic shapes, the printed ink lines also shrank, creating patterns of channels and microwells: perfect for the mixing of fluids and moving of cells she needed to perform her experiments.

Now a UC Irvine assistant professor in biomedical engineering, Khine continues to use her improvised approach to forge various types of chips for microfluidics applications like solar cell concentrators, point-of-care molecular diagnostics and stem cell studies. She can go from design concept to working device, all in a matter of minutes, fashioning both molds and finished devices.

“A lot of companies are showing interest in this for in vitro diagnostics because it’s an alternative that doesn’t require expensive equipment,” Khine says. “All you need is a printer and a toaster oven.” Microfabrication generally requires a clean room, high-end lithographic tools and long processing times.

Khine’s discovery led to UC Merced’s first startup, Shrink Nanotechnologies, the exclusive licensee of her patent-pending devices. (Shrink is actually Khine’s second startup; while in graduate school, she cofounded Fluxion Biosciences in San Francisco, based on her dissertation work on single-cell electroporation.) Last year the Shrinky Dink approach also got the attention of MIT’s Technology Review, which recognized her as one of its select TR35 Young Innovators under age 35.

SERIOUS FUN: Khine prints patterns onto Shrinky Dinks using a laser-jet printer, then heats them in a toaster oven. As they flatten out into hard plastic shapes, the printed ink lines also shrink, creating patterns of channels and microwells that are perfect for her microfluidics experiments. (Reproduced by Permission of The Royal Society of Chemistry.)

Khine says she has the best job in the world, although she never imagined herself holding a faculty position in engineering or creating an international stir in the scientific literature.

“I never thought I would go into academia,” Khine says. “I struggled the whole time I was at Berkeley, but Luke [her advisor Luke Lee, professor of bioengineering and director of the Berkeley Sensor & Actuator Center and Biomolecular Nanotechnology Center] was very encouraging and thought I would make a great professor.” She landed her first academic position at UC Merced, which she found inspiring but rigorous. As a “founding” faculty member, she was doing not only teaching and research, but also a huge amount of groundwork for the School of Engineering and the fledgling campus.

“Everything needed to be done,” Khine recalls. “You had to be on half a dozen faculty searches, the building committee, the parking committee. My research was just beginning to take off, but the only time I had to do it was in the middle of the night.” When an opportunity opened up at UC Irvine’s Henry Samueli School of Engineering, she made the switch.

The daughter of a pathologist and a chemist, Khine was originally inspired by the late Dean Richard Newton’s work on technologies for the developing world. She focuses on low-cost point-of-care diagnostics: inexpensive, microscale devices (think home-pregnancy test) that have the potential to move testing and assays from big medical labs to doctors’ offices and patients’ bedsides. The technology has huge potential for cost savings and increased efficiencies in diagnosis and treatment, with an estimated U.S. market of $20 billion by 2014, and major implications for improving health care delivery in developing nations. Khine is investigating leads for applications in Honduras, India and other poor, rural areas that lack medical facilities and staff.

“Bioengineering is so young, and the energy in the field is palpable,” Khine says. “I hope I get to do this for the rest of my life.”