Print and plug

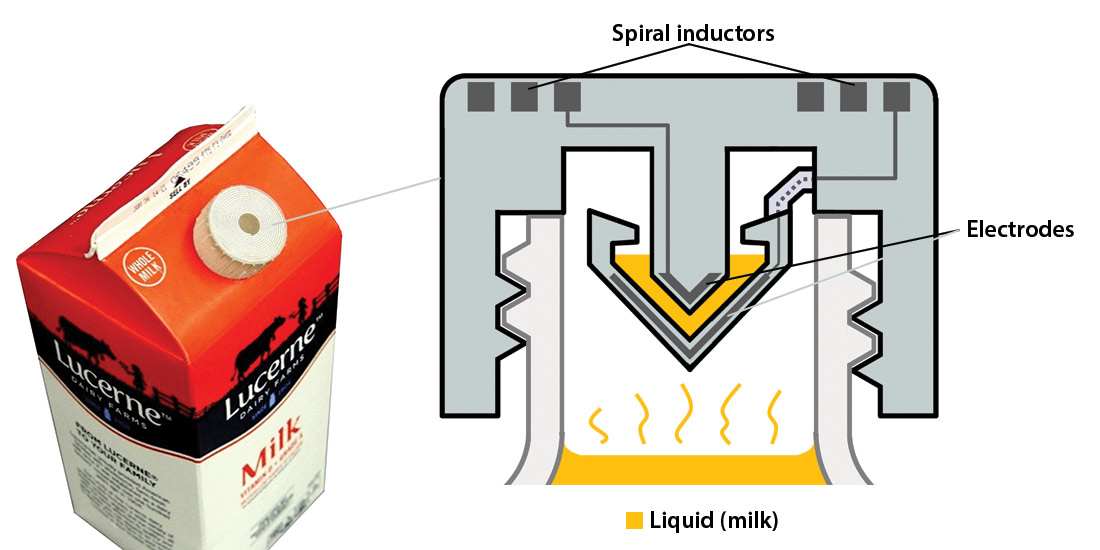

Makers and tinkerers may soon have a new source of electronic components: their personal 3-D printer. Mechanical engineering professor Liwei Lin led a team to demonstrate the potential of 3-D printers to produce not only standard components like resistors, inductors and capacitors, but also custom devices for specific applications — in this test case, a novel wireless sensor integrated into a milk-carton cap to detect spoilage.

Granted, 3-D printers can’t do all the work themselves. While plastic polymers offer flexibility and precision as building blocks of miniature and one-off objects, they don’t conduct electricity. The researchers solved this problem by building solid shapes of plastic and wax, removing the wax, and injecting silver into the voids left behind. The form of the metal determined the components’ final function — thin wires as resistors, flat plates as capacitors, spiral coils as inductors — all on a scale small enough to hide inside a milk cap.

Read more: 3D-printed ‘smart cap’ uses electronics to sense spoiled food