New 3D printer

Rodin’s “The Thinker” statue, as rendered in miniature by a light-based 3D resin printer.

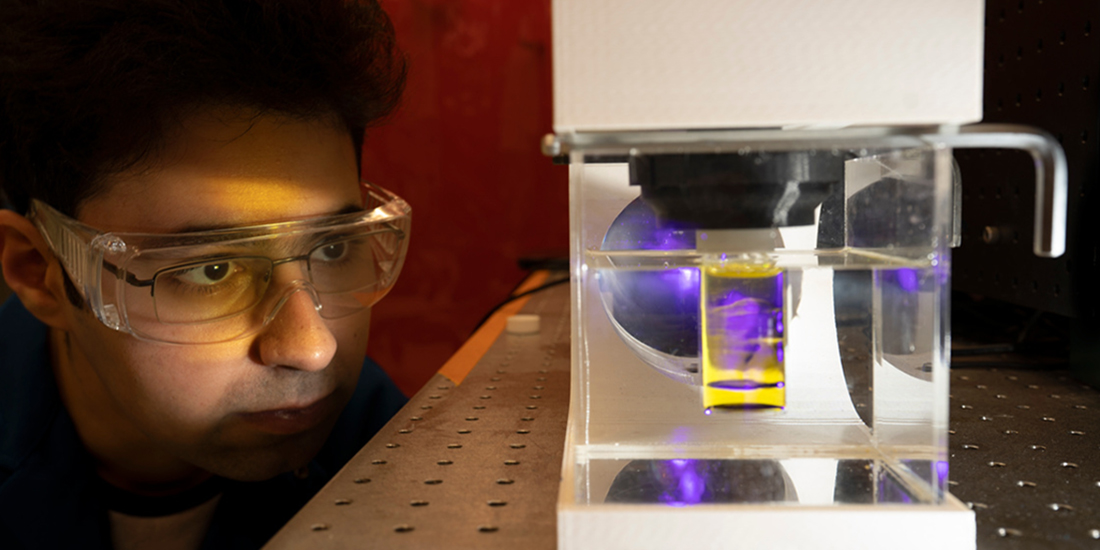

A new 3D printer from the lab of Hayden Taylor, assistant professor of mechanical engineering, has the potential to transform product design. Instead of building an object layer by layer, as other 3D printers do, this printer uses light to shape solid objects out of a viscous liquid in a matter of minutes.

Nicknamed “the replicator” by its inventors — after the Star Trek device that can materialize any object on demand — the 3D printer can create objects that are smoother, more flexible and more complex than what is possible with traditional 3D printers. It can also add new materials to an existing object, such as adding a handle to a metal screwdriver shaft, something current 3D printers have difficulty with.

To create an object, the researchers plug an off-the-shelf video projector into a laptop, which they use to project a series of computed images onto a rotating cylinder. The cylinder is filled with a printing resin that forms a solid when exposed to a certain threshold of light.

The resin is composed of liquid polymers mixed with photosensitive molecules and dissolved oxygen. Light activates the photosensitive compound, which depletes the oxygen. Only in those regions where all the oxygen has been used up do the polymers form the “cross-links” that transform the resin from a liquid to a solid. All uncured resin can be reused, so the technique generates almost no material waste.