Re-engineering Bioproduction

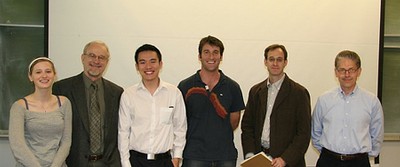

Bio-P Forum organizers, left to right: Lauren Edgecombe, Prof. Lee Schruben, David Zhang, Rick Johnston, Prof. Phil Kaminsky, Prof. Rob Leachman. As the biotech industry has grown, Professors Lee Schruben, Rob Leachman and Phil Kaminsky of Berkeley’s Department of Industrial Engineering and Operations Research (IEOR) have watched the young field bring lifesaving new drugs to market. They have also seen that their potential benefit to society isn’t always realized when these drugs are priced out of reach or when stocks run short. Recognizing that some good IEOR principles could address these problems, they organized the first NSF symposium on Biomanufacturing and Logistics Systems in 2006.

Bio-P Forum organizers, left to right: Lauren Edgecombe, Prof. Lee Schruben, David Zhang, Rick Johnston, Prof. Phil Kaminsky, Prof. Rob Leachman. As the biotech industry has grown, Professors Lee Schruben, Rob Leachman and Phil Kaminsky of Berkeley’s Department of Industrial Engineering and Operations Research (IEOR) have watched the young field bring lifesaving new drugs to market. They have also seen that their potential benefit to society isn’t always realized when these drugs are priced out of reach or when stocks run short. Recognizing that some good IEOR principles could address these problems, they organized the first NSF symposium on Biomanufacturing and Logistics Systems in 2006.

The event struck a nerve, and all the new connections and possibilities could not wait another year. So grad student Rick Johnston launched a weekly Bioproduction Forum that has attracted industry bigwigs from around the world and academics from eight campus departments. The biotech industry seems ripe for a revolution, and if it occurs, you’ll likely be able to trace its agents provocateurs back to IEOR’s Bioproduction Forum.

“The speakers have been fantastic,” says Schruben. “In my 30-plus years in academia, I’ve never seen a forum organized by a grad student become so popular. My only concern is sustainability. We’re a small department and there are no dedicated resources for this; it’s all Rick’s volunteer work.”

Biopharmaceutical production is a classic IEOR challenge, a tangle of complexities and constraints. The drugs are enormous molecules made by genetically engineered bacteria or living tissues, and they don’t always come out exactly the same, even in controlled environments. For public safety, the entire process is heavily regulated, and regulations covering allowable manufacturing equipment, dosage ranges and even expiration dates vary from country to country. Many of the most popular “blockbuster” biopharmaceuticals come from huge factories that manufacture a single drug in thousands of “flavors” to sell into different markets.

“To contain contamination, you can only manufacture one batch at a time, and then all the equipment is sterilized. It’s like building a car, where the entire assembly line waits for the one car to be finished, then shuts down for steam cleaning before starting on the next one,” explains Leachman.

“And if the FDA comes in and finds an employee wearing incorrect attire, or that something was put in the wrong freezer, the whole batch has to go,” adds Johnston.

Against such challenges, Bioproduction Forum attendees seek solutions in a collaborative atmosphere. A wise engineer of human systems, Johnston maintains the proper tone by imposing a rule that speakers share problems and ask questions rather than present so-called success stories. “We want to know, ‘What are you trying to do?’ We don’t want to hear about how great you are,” he explains.

The IEOR problem-solving has already begun. Leachman developed a logistics planning engine that’s now being used by Bayer HealthCare. Looking ahead, Schruben envisions forming an industry consortium that can do things like establish unified standards and benchmark production levels across companies, so they can all see how they’re competing.

But the first step, argues Schruben, is getting biotech research companies to think about production issues sooner. “One question that drug discovery people should have in the backs of their minds is, what if it does work? It’s socially irresponsible to come out with a cure if few people are rich enough to afford it. Some researchers think, let’s find that molecule, let’s get that Nobel Prize in medicine, and let someone else worry about how to get it out there. But to save millions of lives, you have to make millions of doses, and you have to make them safe, effective and cheap. That’s what IEOR does.”

The biopharmaceutical industry is traditionally resistant to change due to the enormous costs of researching new drugs, getting them tested and approved and building up production capacity. But the rewards are high. Johnston recalls one Bioproduction Forum where an audience member raised his hand before the speaker even began.

“He told the speaker, ‘I just want to thank you for saving my life. I had cancer and underwent successful chemotherapy.’ The entire tone of the presentation was changed by that. Everyone there knew this wasn’t like you have someone up there talking about how they made a computer run faster.”