Images courtesy the researchers

Images courtesy the researchersBring in the reinforcements

Since the mid-19th century, engineers have reinforced concrete with steel rebar. But today, engineers are exploring the potential to reinforce concrete with polymers, which are lightweight, don’t corrode and, due to an abundance of recyclable materials, could be cheap to produce.

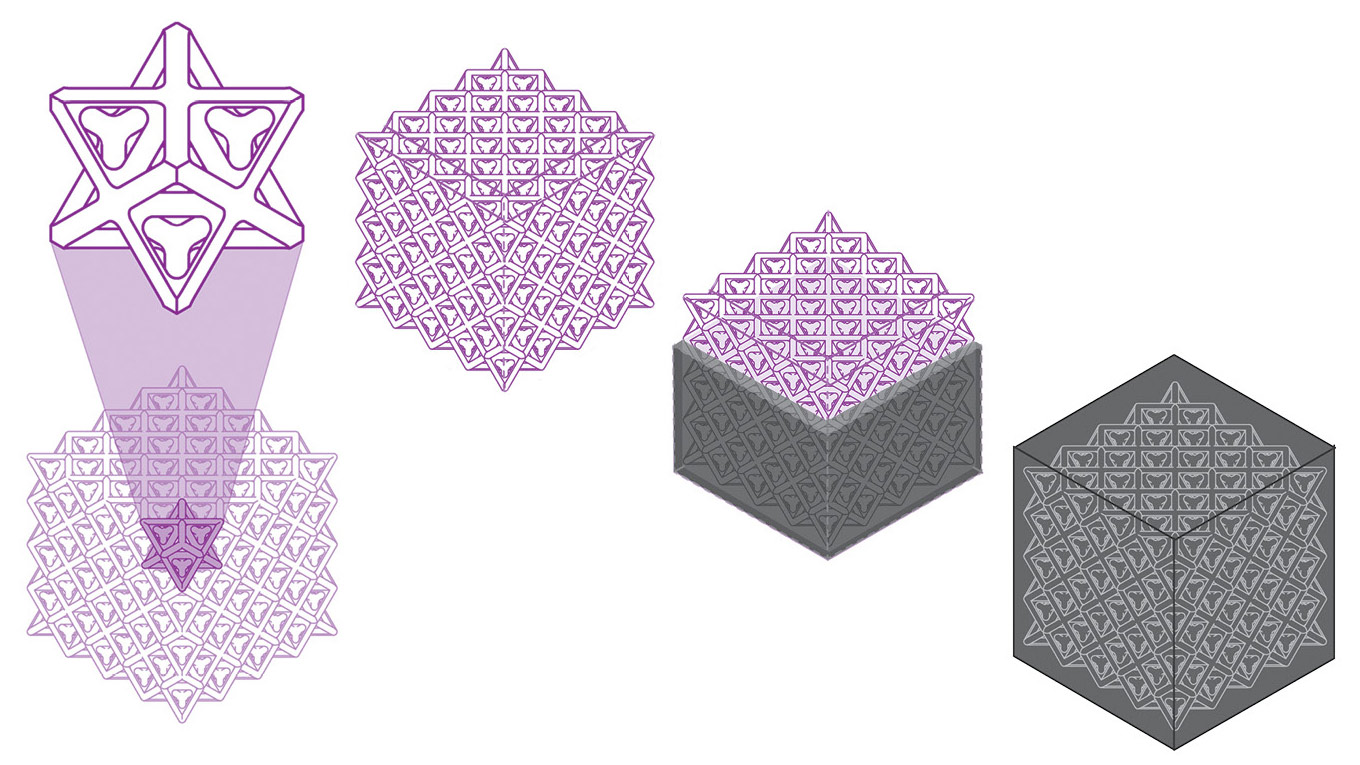

In a study led by Hayden Taylor, associate professor of mechanical engineering, researchers developed a new way to reinforce concrete by using a 3D printer to build octet lattices out of polymer and then filling them with ultra-high performance concrete (UHPC), which is four times stronger than conventional concrete in compression. The work was done with civil and environmental engineering professor Claudia Ostertag’s lab, building upon a previous collaboration to create octet-lattice structures from UHPC by using 3D-printed molds.

In creating the octet lattices, the team tested two different polymers: polylactic acid (PLA), which is easy to 3D print but more brittle than other polymers, and acrylonitrile butadiene styrene (ABS), which is tougher than PLA and used in everything from Lego bricks and motorcycle helmets to whitewater canoes and car bumpers. Switching from PLA to ABS made no significant difference in compressive tests; all of the lattice-reinforced concrete samples scored high in strain energy density values, meaning they were able to absorb a lot of energy.

The engineers also experimented with the amount of lattice reinforcement used in the concrete. While increasing the amount of polymer in the samples slightly decreased their compressive strength, it actually increased their peak loads in bending tests. However, the samples with less polymer were just as tough as those with more. Increasing the amount of polymer — and reducing the amount of concrete — could also cut down on a structure’s overall carbon emissions if recycled or bio-based polymers are used.

The next step, said graduate student and study lead author Brian Salazar, will be to determine if different concrete uses would be better served by different lattice shapes. In the future, engineers might determine the best reinforcement geometry for a given project with the help of topology optimization software.

Learn more: Berkeley researchers use 3D printer to make stronger, greener concrete