Control design at Lift Labs

Anupam Pathak’s (B.S. ‘04 ME) idea to build a device to assist people with Parkinson’s disease or essential tremor evolved from helping soldiers survive combat. Pathak started his mechanical engineering doctoral research at the University of Michigan at the height of U.S. troop deployments to Iraq and Afghanistan in 2004. Field reports showed that large numbers of freshly minted troops, with little experience in war zones, were facing stress-induced tremors during combat situations. A soldier with shaky hands is dangerous; the situation was so bad that tremor was affecting casualty rates.

Pathak’s research focused on the actuator, the part of a weapon’s stabilizing device that counters the tremor. He was interested in the research because he liked developing hardware and solving real-world problems. Gradually, he started thinking about other applications of stabilization technology.

By the time he completed his Ph.D. in 2009, he was talking to neurologists at the University of Michigan. “I knew about enhanced tremor due to neurological disorders like Parkinson’s and essential tremor, and I wanted to see if the technology I was working on would be appropriate for that,” Pathak says.

After meeting with neurologists, Pathak found that more than 10 million people in the United States are facing challenges related to tremor. “It turns out that a solution does not exist for a lot of people,” Pathak says. At the time, the only real treatment options were medication or surgery. The medications prescribed for tremor control are beta blockers, which were developed to control blood pressure. They are either ineffective for treating tremor, have side effects, or both. The other treatment option is brain surgery, which is as complicated, risky and expensive as it sounds.

Pathak began spending a lot of time visiting support groups for people with tremor-related problems. “I would attend a meeting, and we weren’t just talking about my product. They were talking about what it is like to have essential tremor, and that’s when it became clear what an emotional toll this condition takes,” Pathak says. He learned two things, he says: one, that tremors have a deep impact on quality of life, affecting a variety of activities from eating and writing to applying make-up and unlocking doors; and two, people with tremors avoid awkward solutions such as large braces or tech-heavy devices. What they wanted was something simple and easy to use.

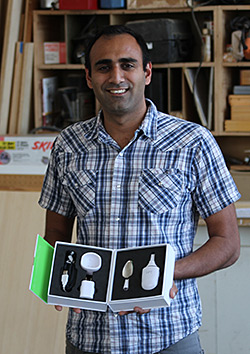

Lift Labs founder and CEO Anupam Pathak in the company’s workshop. (Photo by Daniel McGlynn.)

Pathak and his collaborators were awarded funding from the National Institutes of Health (NIH) to develop a proof of concept for a tremor-stabilizing device. After more than a year of research and development and another round of NIH funding, Pathak founded Lift Labs in 2012. Their first product, based on the NIH-backed research and clinical trials at the University of Michigan hospital, was called Liftware.

At its core, the Liftware device is a mechanism with different attachments; the first is a spoon, which is on the market now, and a fork is in development. The handle for the device contains a sensor, which interacts with the actuator to counter the tremor in a user’s hand. Inside the handle is a rechargeable battery; a charge lasts for several meals. Each aspect, from Liftware’s packaging to the way it is cradled in the battery charger to the method of inserting the attachment to the handle, was designed carefully for the end user. Liftware is compact, and its technology is hidden. “There was a tremendous amount of thought put into how a person is feeling when they are using the device,” Pathak says.

Since founding the company, Pathak has moved back to Bay Area, where he is from. He wanted to be close to his family, and he says that in a region known for innovation, there are support structures for startups. Lift Labs is headquartered in a shared workspace in San Francisco. The company’s products are manufactured in Fremont, which allows Pathak to keep an eye on quality control and deal with the complexities inherent in building a hardware supply chain. During their first product run, which they scrambled to ship by December 2013, Pathak says that he and one of Lift Labs’ first employees, Michael Allen (B.S.’11 ME), sat on the production line and helped assemble the devices because they wanted to make sure everything was perfect. “That’s really what it takes to ship a product,” Pathak says.

While designing, building and getting feedback from Liftware users, Pathak says he thinks back to an engineering ethics class he took as an undergraduate at Berkeley. “We were taught to think about who are you affecting by your work. I think that is so important in how we develop this product.”

For Pathak, impact extends beyond design. Lift Labs is currently running a crowd-funding campaign to raise money for people unable to afford the $295 Liftware device. The company will match the donations they receive and apply the funds towards getting the technology into as many hands as possible.

More Liftware attachments are in the works, as well as other stabilizing devices and technologies. “I didn’t start a business because I want to be a businessman,” Pathak says, “I started this because I want to keep creating things, and it will be so great to have a space to do that, and to do it freely.”